Categories

New products

-

Lens Ring Joint Gasket

Looking for more information on Lens Ring Joint Gasket? We are the China leading Supplier of Lens Ring Joint Gasket.Any need of Lens Ring Joint Gasket,please feel free to congtact us.

-

Double Jacket Gasket

Looking for more information on Double Jacket Gasket? We are the China leading Supplier of Double Jacket Gasket.Any need of Double Jacket Gasket,please feel free to congtact us.

-

Corrugated Gaskets

Looking for more information on Corrugated Gaskets? We are the China leading Supplier of Corrugated Gaskets.Any need of Corrugated Gaskets,please feel free to congtact us.

-

Pure PTFE Gasket

Looking for more information on Pure PTFE Gasket? We are the China leading Supplier of Pure PTFE Gasket.Any need of Pure PTFE Gasket,please feel free to congtact us.

-

PTFE Envelope Gasket

Looking for more information on PTFE Envelope Gasket? We are the China leading Supplier of PTFE Envelope Gasket.Any need of PTFE Envelope Gasket,please feel free to congtact us.

Flange gasket

HIT:29 DATE:2015-3-25

A flange gasket is a type of gasket made to fit between two sections of pipe that are flared to provide higher surface area.

Flange gaskets come in a variety of sizes and are categorized by their inside diameter and their outside diameter.

There are many standards in gasket for flanges of pipes. The gaskets for flanges can be divided in major 4 different categories:

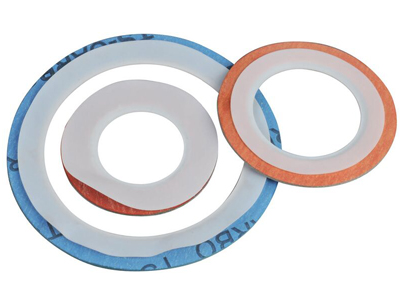

1.Sheet gaskets

2.Corrugated metal gaskets

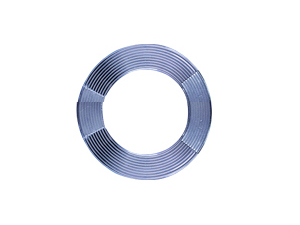

3.Ring gaskets

4.spiral wound gaskets

Sheet gaskets are simple, they are cut to size either with bolt holes or without holes for standard sizes with various thickness and material suitable to media and temperature pressure of pipeline.

Ring gaskets also known as RTJ. They are mostly used in offshore oil- and gas pipelines and are designed to work under extremely high pressure. They are solid rings of metal in different cross sections like oval, round, octagonal etc. Sometimes they come with hole in center for pressure .

Spiral wound gaskets are also used in high pressure pipelines and are made with stainless steel outer and inner rings and a center filled with spirally wound stainless steel tape wound together with graphite and PTFE, formed in V shape. Internal pressure acts upon the faces of the V, forcing the gasket to seal against the flange faces.